Quality Excellence

Our commitment to quality is unwavering. Every product undergoes rigorous testing and inspection to ensure it meets the highest standards of precision and reliability.

Precision Tolerances

Maintaining tolerances as tight as ±0.01mm for critical components

Advanced Testing

State-of-the-art testing equipment for dimensional and material analysis

Quality Control

Multi-stage inspection process ensuring zero-defect delivery

Certified Processes

All processes certified under international quality standards

Certifications

- ISO 9001:2015 Quality Management

- ISO 14001:2015 Environmental Management

- OHSAS 18001 Occupational Health & Safety

- RoHS Compliance Certification

Quality Process

- 1Incoming Material Inspection

- 2In-Process Quality Monitoring

- 3Dimensional Verification

- 4Material Property Testing

- 5Final Product Inspection

- 6Packaging & Delivery Audit

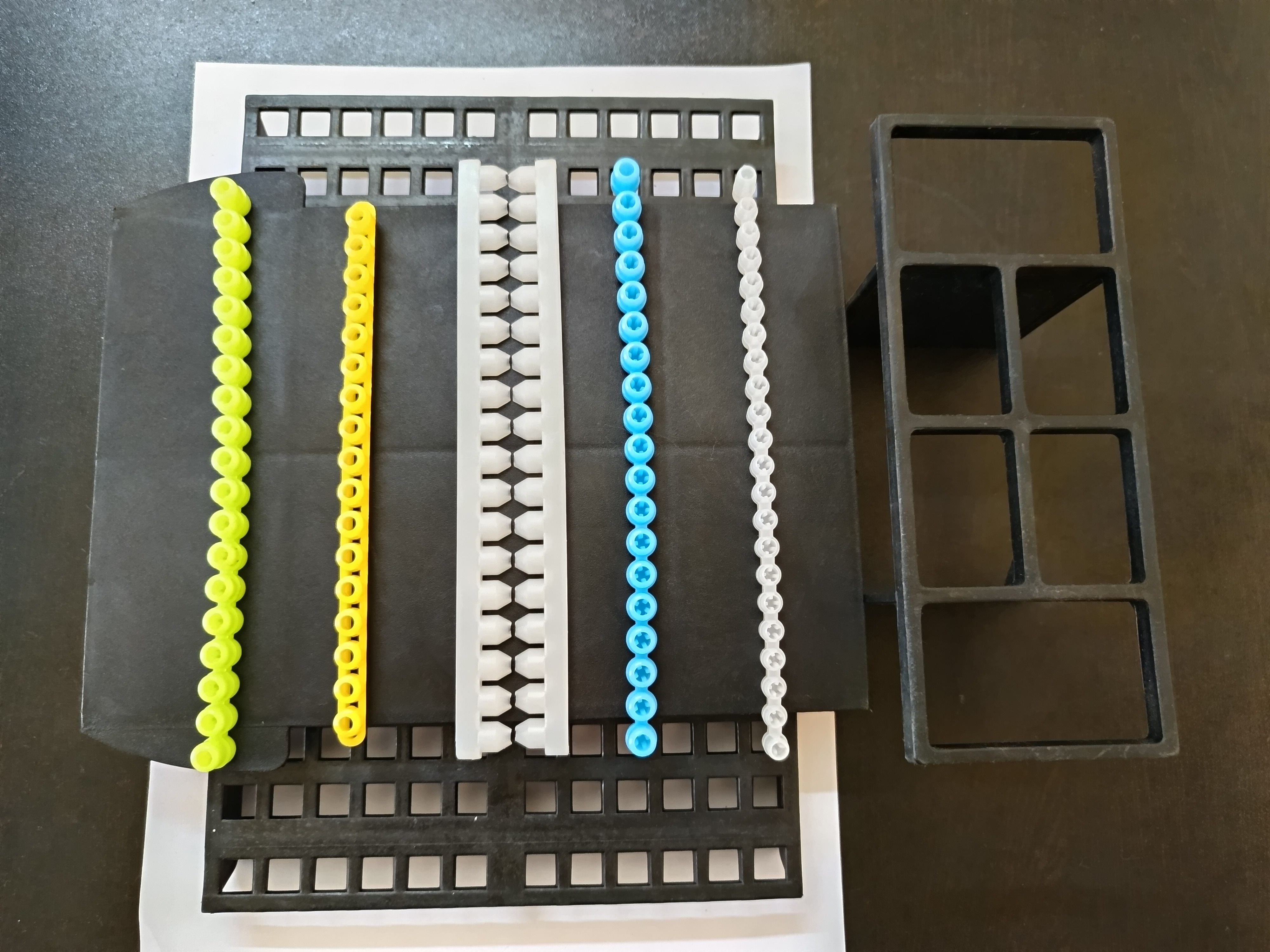

High-Resolution Product Gallery

Showcasing the precision and quality of our polymer products

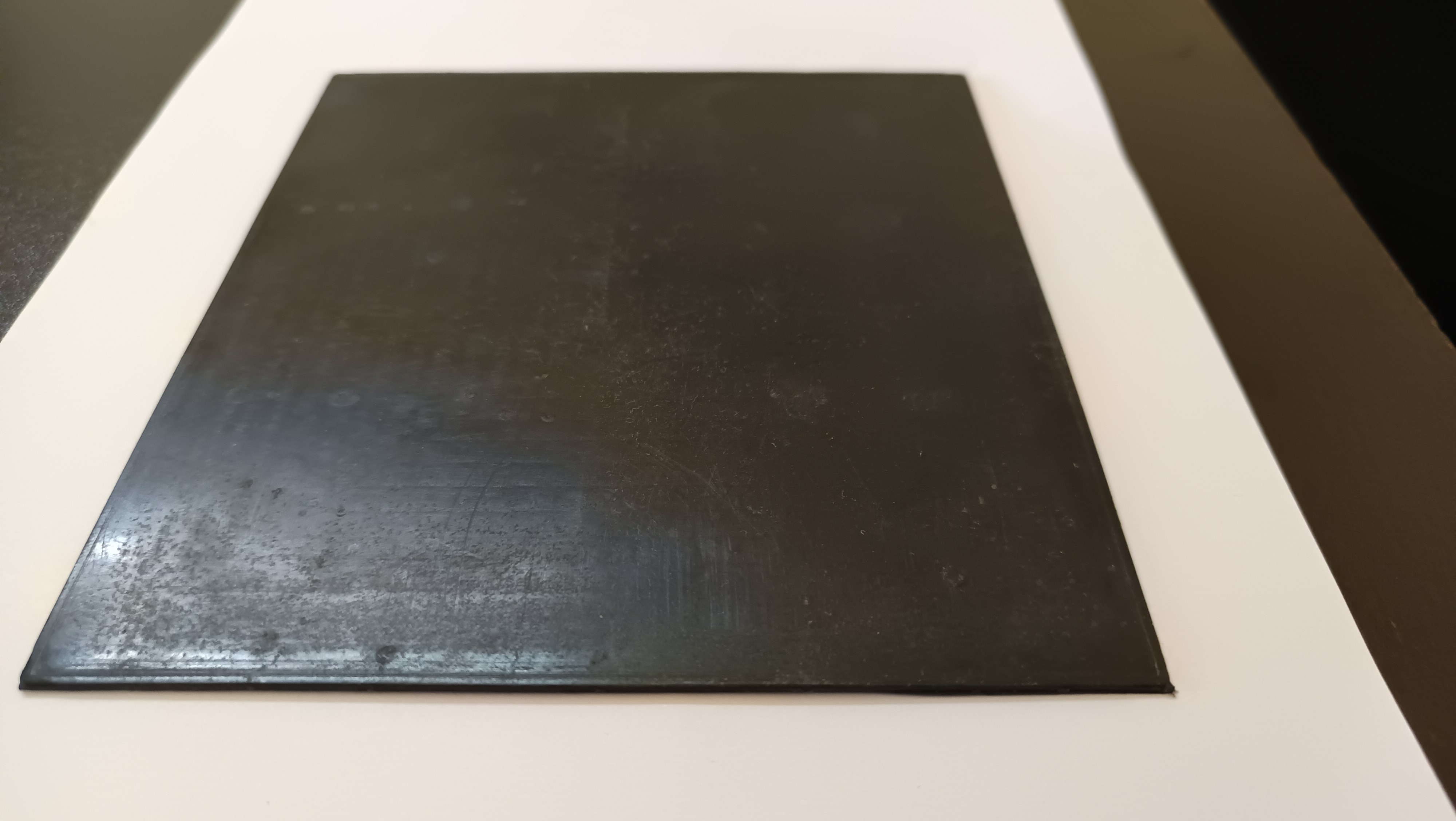

Precision Packing Shims

Ultra-precise 2MM components with tight tolerances

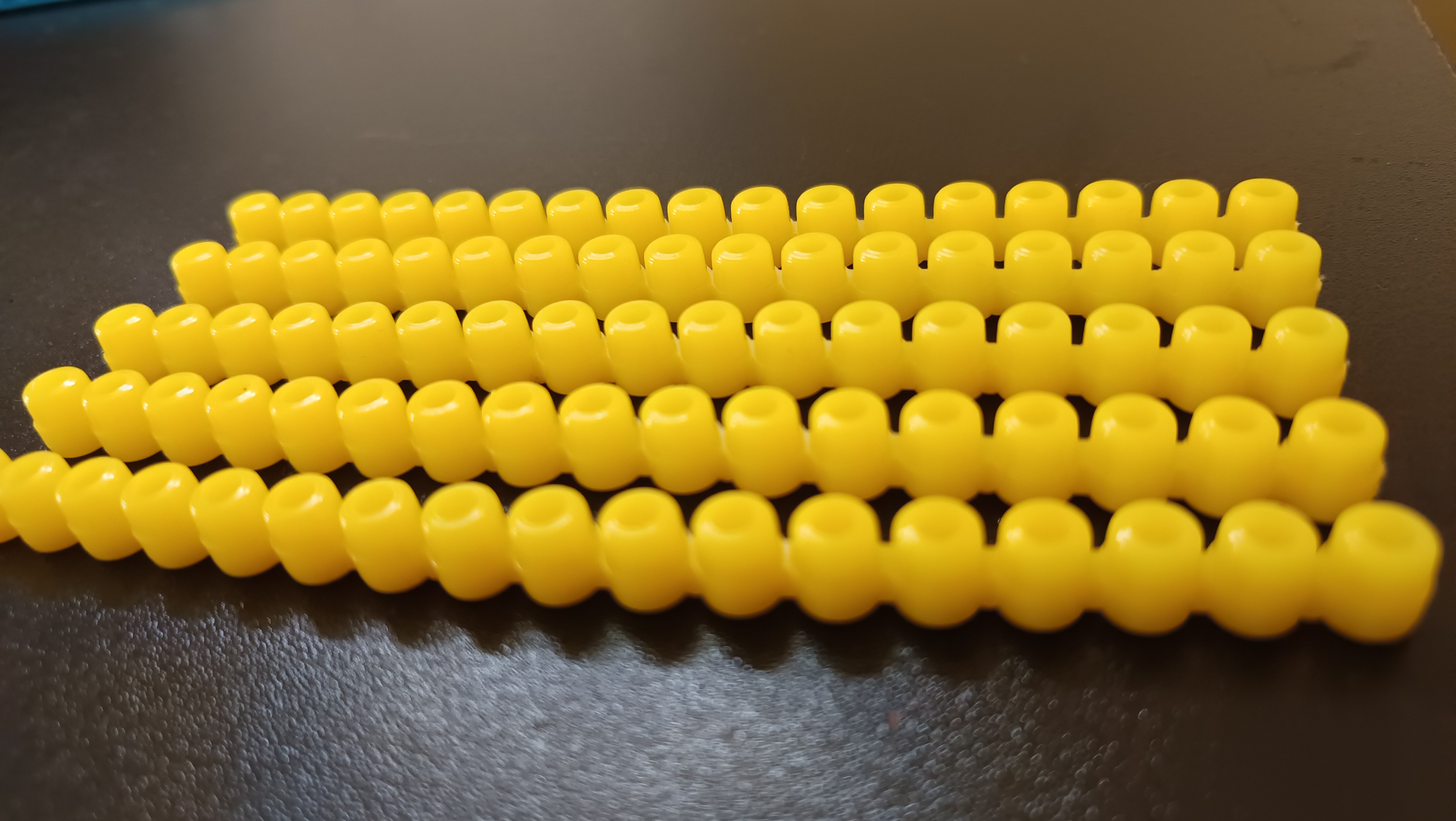

Battery Terminal Quality

11MM terminals meeting automotive standards

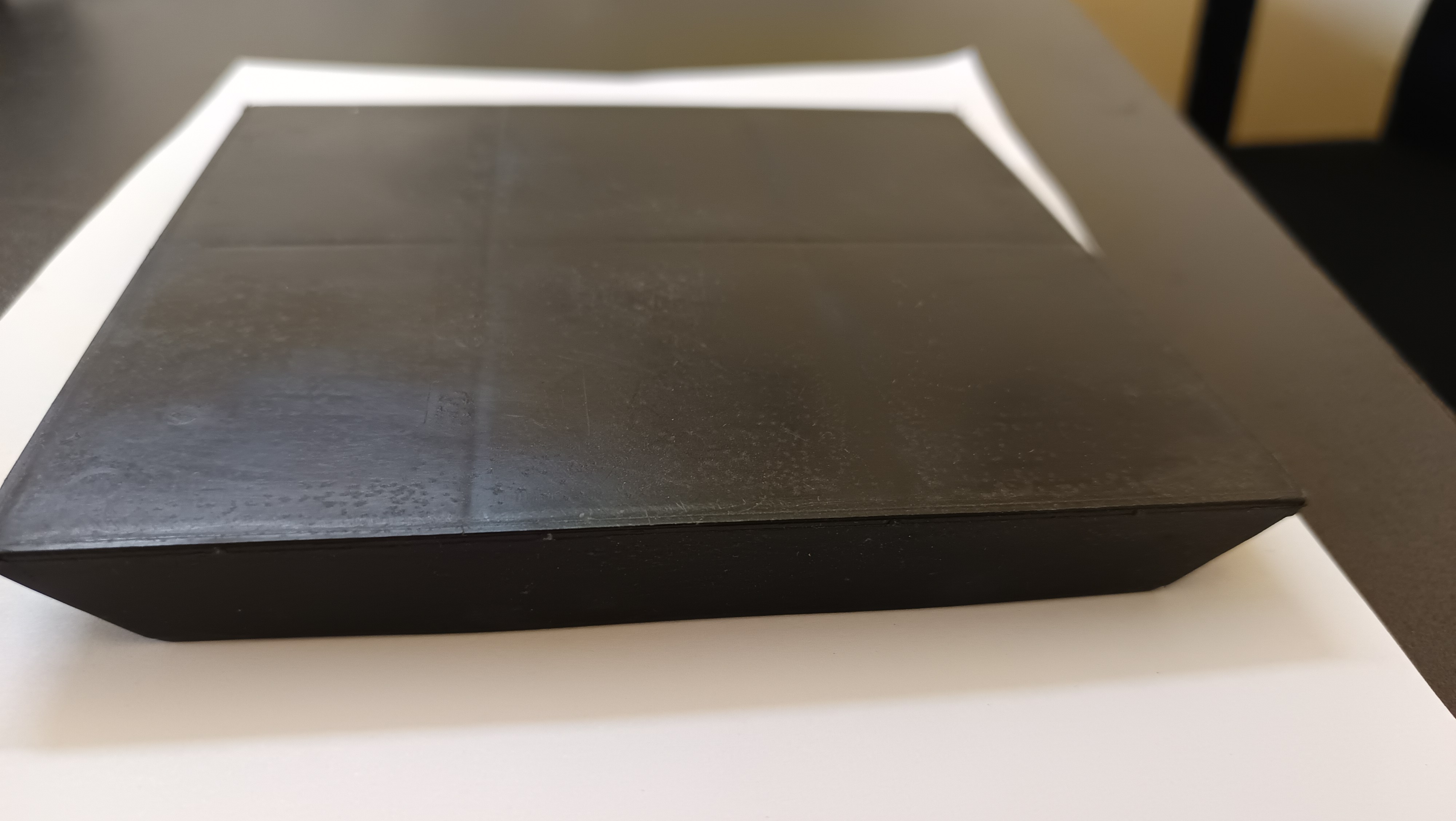

Industrial Grade Components

17BB battery bars for heavy-duty applications

Terminal Component Excellence

17MM components with superior conductivity

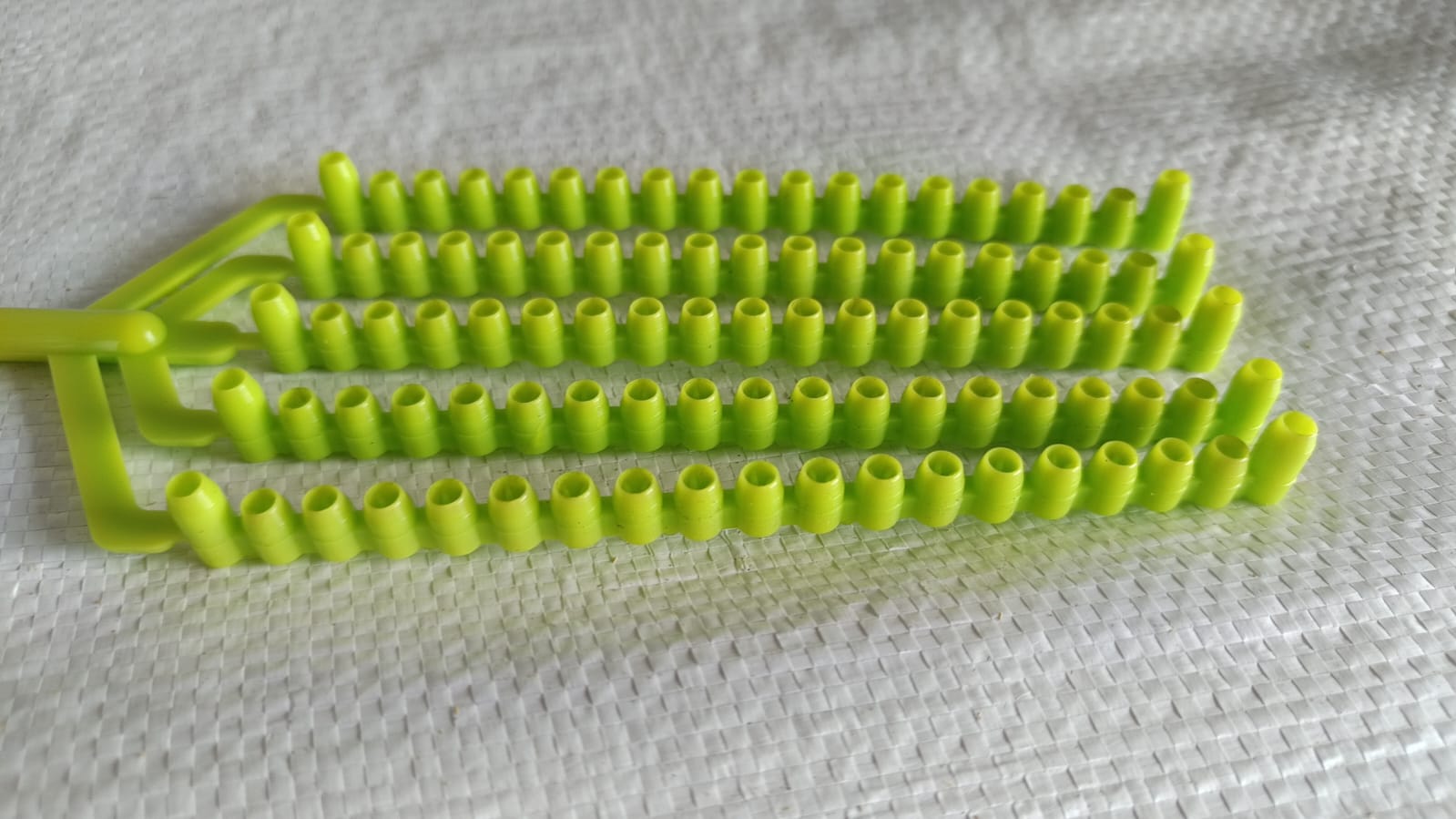

Eco-Friendly Solutions

Sustainable green polymer components

Complete Assembly Quality

Comprehensive quality control for all assemblies

Our Quality Commitment

At VM Polymers, quality isn't just a goal—it's our foundation. We invest in the latest technology, maintain rigorous standards, and continuously improve our processes to deliver products that exceed expectations. Our ISO certifications and zero-defect track record speak to our unwavering commitment to excellence.